Introduction

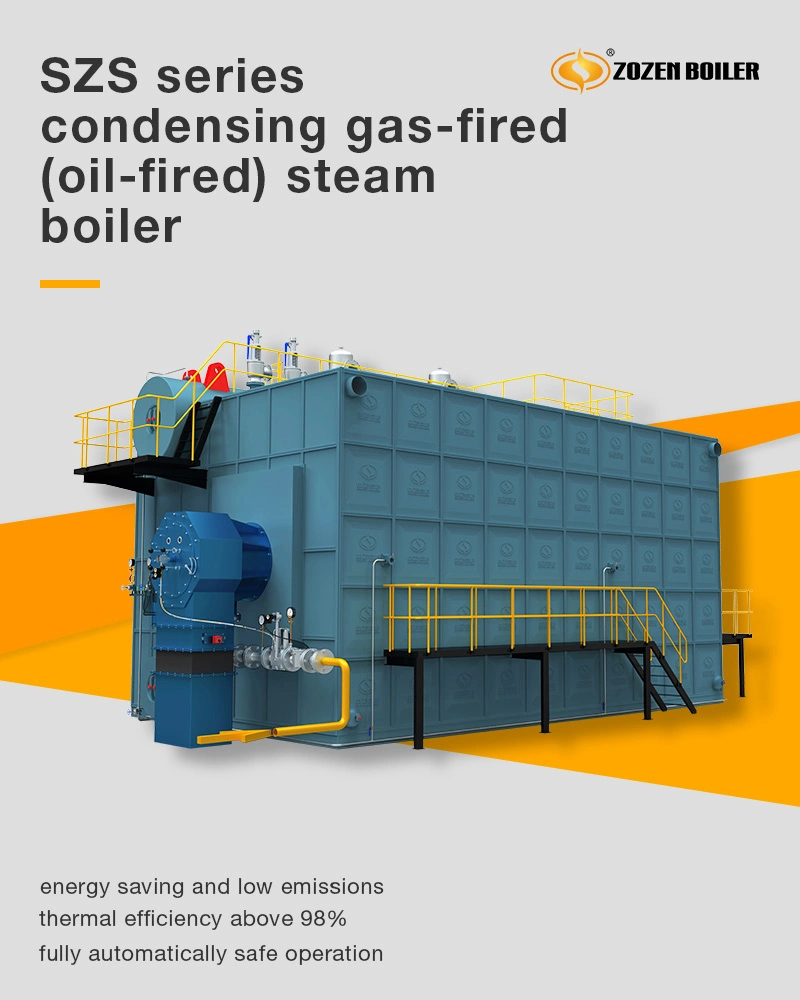

SZS series boiler is designed with longitudinal double drums and " D " type chamber structure. Furnace is placed on the right and convection tube bank is on the left, super heater is arranged at convection tube bank. The body is fixed on the basement by middle and both end flexible supports and make the boiler expand horizontally sideways. Around the furnace is membrane water cooling tube wall. Furnace and tube bank are totally separated by the membrane water tube cooling wall at the left side of the furnace. The back part of bundle is sparse shift structure, front part is aligned structure. Smoke from furnace outlet enters re-burning chamber, convection tube bank area and then from left front part enters spiral fine coil economizer and condenser, and finally is discharged to atmosphere through chimney.

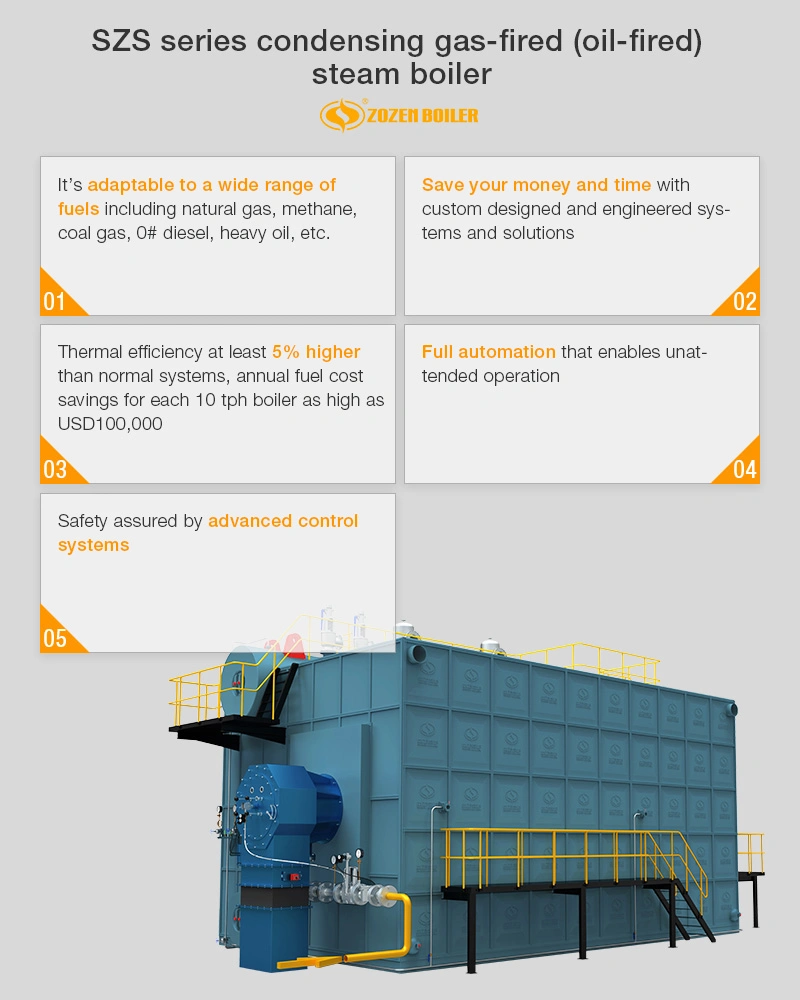

-Product Features:

1.Due to combustion chamber applying whole membrane water cooling structure and micro-positive pressure combustion, there is no smoke leakage and no pollution to the environment.

2.With anti-explosion door and flame detector, the boiler is safer and reliable.

3.The water circulation is enforced. That can ensure every heating area can be cooled and no vaporization happens.

4.We adopt spiral finned tube economizer. That can reduce the smoke temperature and increase the heat efficiency up to 92%.

5.Compact structure. It covers small space in the boiler house.

6.The manholes are designed at each end of the double drums, and the check door is designed at the back of boiler. The door is easy to open and is very convenient to do maintenance and cleaning job.

7.The boiler is assembled for delivery. It is easy to transport and installed.

8.The boiler achieves full automation control. It is easy to operate.

| Product thermal capacity: | 10-100 t/h |

| Working pressure: | 2.5-9.8 Mpa |

| Outlet temperature: | 194-540 °C |

| Available fuel: | Nature gas, coke oven gas, blast furnace gas, carbon black off-gas, biogas, methanol, LPG, diesel, heavy oil, light oil, crude oil, etc. |

| Available industries: | Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc |

| Model | Rated evaporation(t/h) | Rated working pressure(MPa) | Rated steam temperature(ºC) | Thermal efficiency(%) | Maximum transport size(m) (L×W×H) |

| SZS20-1.25-Q.Y | 20 | 1.25 | 194 | >98 | 8.9×3.9×4.0 |

| SZS20-1.6-Q.Y | 20 | 1.6 | 204 | >98 | 8.9×3.9×4.0 |

| SZS20-2.5-Q.Y | 20 | 2.5 | 225 | >98 | 8.9×3.9×4.0 |

| SZS25-1.25-Q.Y | 25 | 1.25 | 194 | >98 | 10.5×4.2×4.2 |

| SZS25-1.6-Q.Y | 25 | 1.6 | 204 | >98 | 10.5×4.2×4.2 |

| SZS25-2.5-Q.Y | 25 | 2.5 | 225 | >98 | 10.5×4.2×4.2 |

| SZS30-1.25-Q.Y | 30 | 1.25 | 194 | >98 | 10.5×4.3×4.3 |

| SZS30-1.6-Q.Y | 30 | 1.6 | 204 | >98 | 10.5×4.3×4.3 |

| SZS30-2.5-Q.Y | 30 | 2.5 | 225 | >98 | 10.5×4.3×4.3 |

| SZS35-1.25-Q.Y | 35 | 1.25 | 194 | >98 | 11.3×4.3×4.3 |

| SZS35-1.6-Q.Y | 35 | 1.6 | 204 | >98 | 11.3×4.3×4.3 |

| SZS35-2.5-Q.Y | 35 | 2.5 | 225 | >98 | 11.3×4.3×4.3 |

| SZS40-1.25-Q.Y | 40 | 1.25 | 194 | >98 | 12.4×4.4×4.6 |

| SZS40-1.6-Q.Y | 40 | 1.6 | 204 | >98 | 12.4×4.4×4.6 |

| SZS40-2.5-Q.Y | 40 | 2.5 | 225 | >98 | 12.4×4.4×4.6 |

| SZS50-1.25-Q.Y | 50 | 1.25 | 194 | >98 | 15.6×4.4×4.6 |

| SZS50-1.6-Q.Y | 50 | 1.6 | 204 | >98 | 15.6×4.4×4.6 |

| SZS50-2.5-Q.Y | 50 | 2.5 | 225 | >98 | 15.6×4.4×4.6 |

| SZS65-1.25-Q.Y | 65 | 1.25 | 194 | >98 | 11.5×1.5×1.8 |

| SZS65-1.6-Q.Y | 65 | 1.6 | 204 | >98 | 11.5×1.5×1.8 |

| SZS65-2.5-Q.Y | 65 | 2.5 | 225 | >98 | 11.5×1.5×1.8 |

| SZS75-1.25-Q.Y | 75 | 1.25 | 194 | >98 | 12×1.5×1.8 |

| SZS75-1.6-Q.Y | 75 | 1.6 | 204 | >98 | 12×1.5×1.8 |

| SZS75-2.5-Q.Y | 75 | 2.5 | 225 | >98 | 12×1.5×1.8 |

| SZS100-1.25-Q.Y | 100 | 1.25 | 194 | >98 | 13×1.5×1.8 |

| SZS100-1.6-Q.Y | 100 | 1.6 | 204 | >98 | 13×1.5×1.8 |

| SZS100-2.5-Q.Y | 100 | 2.5 | 225 | >98 | 13×1.5×1.8 |