PRODUCT DESCRIPTION

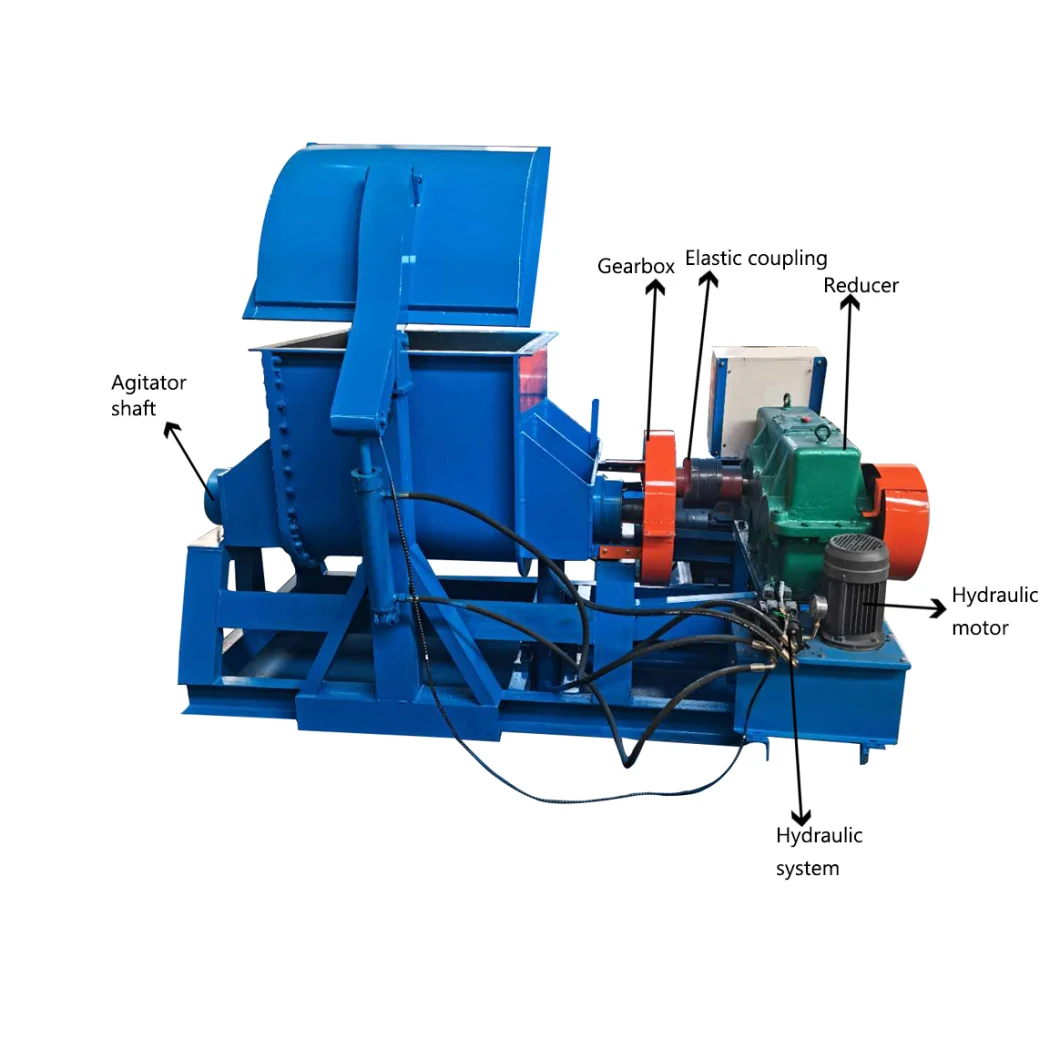

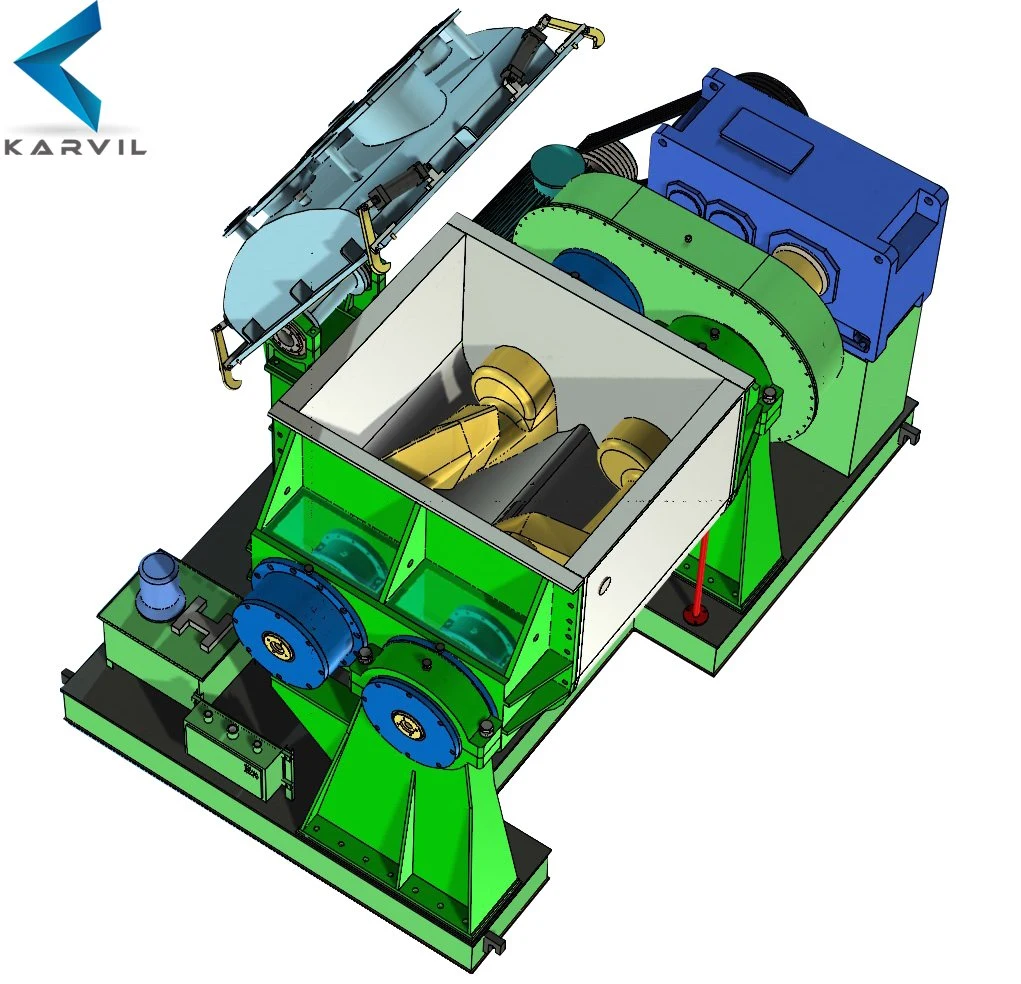

The Sigma mixer is consist of mixing chamber, frame support, hydraulic system, electric control system, discharge system and two Z shape blade in the chamber drove by the motor, and the two blades rotating with different speed but can be controlled by the inverter. The sigma blade mixer caused by a pair of mutually cooperating and rotating Z blades to produce a strong shearing action so that the semi-dry state or the rubbery viscous plastic material enables the material to react quickly to obtain a uniform mixing.

Independent distribution box (control panel), which can realize the separate and precise control of stirring speed, heating or cooling temperature, stirring and discharging system.

The Sigma mixer is consist of mixing chamber, frame support, hydraulic system, electric control system, discharge system and two Z shape blade in the chamber drove by the motor, and the two blades rotating with different speed but can be controlled by the inverter. The sigma blade mixer caused by a pair of mutually cooperating and rotating Z blades to produce a strong shearing action so that the semi-dry state or the rubbery viscous plastic material enables the material to react quickly to obtain a uniform mixing.

Independent distribution box (control panel), which can realize the separate and precise control of stirring speed, heating or cooling temperature, stirring and discharging system.

PRODUCT ADVANTAGES

Liquid addition: The liquid material can be atomized into the mixer by spraying so that a small amount of liquid can be mixed evenly after adding.

Heating and stirring: The mixer can be heated and cooled during the stirring process to meet the constant temperature requirements of various materials during the stirring process.

The equipment can be designed for stand-alone operation, manual feeding, manual packaging and other functions; at the same time, it can also be designed for production line operation, automatic batching, automatic mixing, automatic packaging and other functions.

Liquid addition: The liquid material can be atomized into the mixer by spraying so that a small amount of liquid can be mixed evenly after adding.

Heating and stirring: The mixer can be heated and cooled during the stirring process to meet the constant temperature requirements of various materials during the stirring process.

The equipment can be designed for stand-alone operation, manual feeding, manual packaging and other functions; at the same time, it can also be designed for production line operation, automatic batching, automatic mixing, automatic packaging and other functions.

MAIN FEATURES

1.Structure: Including kneading/mixing system, machine base, hydraulic system, transmission system, electric control system, heating system (optional), cooling system (optional), a vacuum system (optional)

2.Discharging: Tilting discharging

Screw extruding discharging

Ball valve/bottom plate (manual, electrical, pneumatic)

3.Heating: Electric heating, hot water heating, hot oil heating and steam heating.

Cooling: Z blades water cooling, mixing chamber with a jacket for cooling purpose.

4.Vacuum system: Water-ring vacuum pump and buffer tank.

1.Structure: Including kneading/mixing system, machine base, hydraulic system, transmission system, electric control system, heating system (optional), cooling system (optional), a vacuum system (optional)

2.Discharging: Tilting discharging

Screw extruding discharging

Ball valve/bottom plate (manual, electrical, pneumatic)

3.Heating: Electric heating, hot water heating, hot oil heating and steam heating.

Cooling: Z blades water cooling, mixing chamber with a jacket for cooling purpose.

4.Vacuum system: Water-ring vacuum pump and buffer tank.

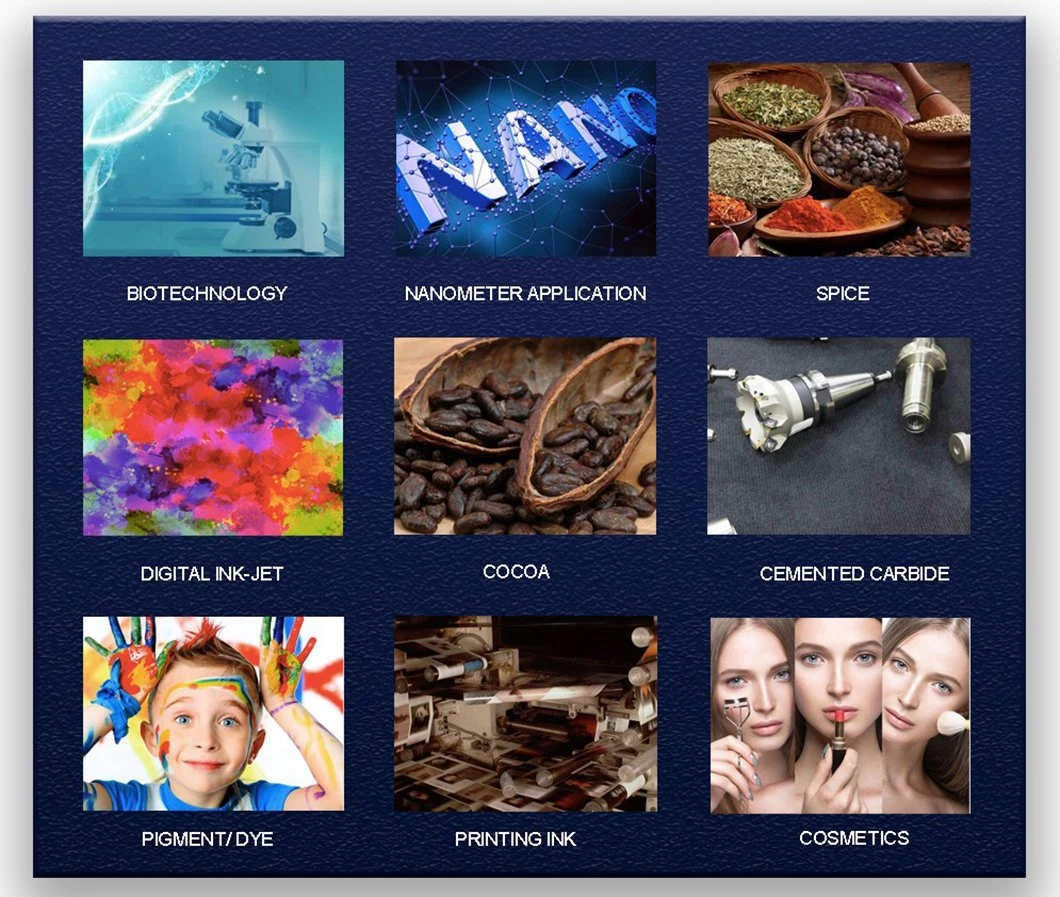

APPLICATION RANGE

Widely used in mixing and kneading of low-to-high viscosity products in many industries such as BMC/DMC, Chewing gum, candy/sugar paste, plastic/silly putty, hot melt adhesive, silicon compound, CMC/Cellulose, Electrode paste, carbon, pencil leads, soap, pigments, inks, plastic, etc.

Widely used in mixing and kneading of low-to-high viscosity products in many industries such as BMC/DMC, Chewing gum, candy/sugar paste, plastic/silly putty, hot melt adhesive, silicon compound, CMC/Cellulose, Electrode paste, carbon, pencil leads, soap, pigments, inks, plastic, etc.

| Type | NH-5 | NH-10 | NH-100 | NH-300 | NH-500 | NH-1000 | NH-1500 | NH-2000 | NH-3000 | NH-4000 | NH-5000 | |

| Volume (L) | 5 | 10 | 100 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | |

| Rotation Speed (rpm) | 33 23 | 33 23 | 35 22 | 37 21 | 37 21 | 35 25 | 30 16 | 30 16 | 38 27 | 38 27 | 38 27 | |

| Main Motor Power (kW) | 0.75 | 1.1 | 3-7.5 | 11-30 | 15-37 | 22-90 | 22-90 | 30-110 | 30-110 | 45-110 | 55-132 | |

| Heating Methods | Steam Pressure (MPa) | 0.3 | ||||||||||

| Electric Power (kW) | 1 | 1 | 4 | 9 | 16.2 | 27 | 32.4 | 40 | 72 | 72 | 96 | |

| Vacuum (MPa) | -0.094 (Vacuum Kneader) | |||||||||||

| Pressure (MPa) | 0.45 (Pressure Kneader) | 0.35 (Pressure Kneader) | 0.3 (Pressure Kneader) | |||||||||

| Weight (Kg) | 300 | 400 | 1250 | 1600 | 3000 | 4500 | 5800 | 6500 | 11000 | 13000 | 21000 | |

ABOUT US

ABOUT US

Shandong Karvil Machinery Technology Co., Ltd. is specializing in the research, design, manufacturing and sales of mixing machines, grinding equipment and reaction machines. The company is committed to the advanced technology of machines, strict quality control standards and perfect sales service experience to achieve a win-win situation with our customers.

Karvil products have been successful used in the field of powder processing, food, medicine, fine chemical industry, cosmetics, adhesives, paints, inks, dyes, pastes, organic solvents and ceramics, etc.

Karvil engineering team constantly explores new technical points and promotes perfect solutions for our clients through efficient communication according to the production application.

Our company has a series of strict standards system to control the purchase of raw materials, the rationality of design, manufacturing process, during the inspection, product inspection, which could ensure the high quality of our products and create value for our clients.

FAQ

1. Manufacturer or trading company?

We are a manufacturer with strict production standards in China.

2. Where is your company?

Our company is located in Yantai, Shandong,--Powder Equipment Industry Belt.

3. About your company's visit?

We can pick you up at Qingdao Airport conveniently, and then we can take you to our factory.

4. What is the main market for your company?

Asia and Africa, Australia, America, Europe.

5. Can you provide customized products?

Yes, we have professional engineers to meet your special design needs, so we can provide customized products.

6. What is your delivery time?

It usually takes about 20 to 30 days, the exact time also depends on the type and quantity of the product.

7. About the product warranty?

Usually, we provide a 1-year warranty for the products that have been sold, but we can also provide life-long service when you need it to maintain a long-term relationship with you.

8. What are the payment terms?

T/T, L/C, et