Product Description:

What is the specification of the machine?

Usage: For rubber calendering, laminating and sheeting.

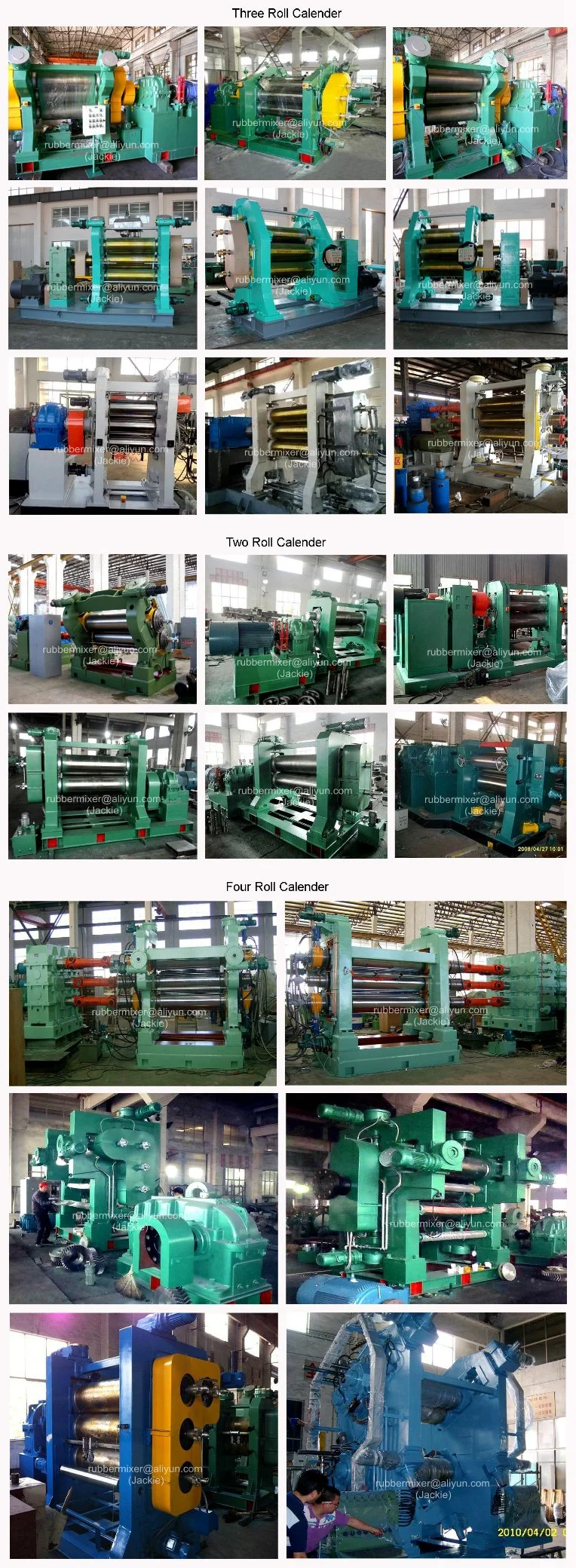

Three Roll Mill Rubber Calender

Roller type: I type, F type (reverse L)

Model: XY-230X635 XY-300X900 XY-360X1120 XY-400X1200

XY-450X1400 XY-560X1700 XY-610X1730

What is the specification of the machine?

Usage: For rubber calendering, laminating and sheeting.

Three Roll Mill Rubber Calender

Roller type: I type, F type (reverse L)

Model: XY-230X635 XY-300X900 XY-360X1120 XY-400X1200

XY-450X1400 XY-560X1700 XY-610X1730

| Model | XY-3I 230 XY-3L 230 XY-3Г 230 | XY-3I 300 XY-3L 300 XY-3Г300 | XY-3I 360 XY-3Г 360 XY-3L 360 | XY-3I 400 XY-3Г 400 | XY-3I 450 XY-3Г 450 | XY-3I 560 XY-3Г 560 | XY-3I 610 XY-3Г 610 | ||

| Roll diameter | mm | 230 | 300 | 360 | 400 | 450 | 560 | 610 | |

| Roll working length | mm | 635 | 900 | 1120 | 1200 | 1400 | 1700 | 1730 | |

| Roll ratio | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | ||

| Middle-roll linear speed | r/min | 2-10 | 2-17 | 0-22 | 23.92 | 2-24.99 | 0-30 | 0-30 | |

| Adjusting nip range | mm | 0-6 | 0-8 | 0-10 | 0-10 | 0-6 | 0-10 | 0-10 | |

| Min.Calendering product thickness | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.15 | |

| Max.calendering product width | mm | 600 | 700 | 900 | 1000 | 1200 | 1500 | 1530 | |

| Motor power | kW | 15 | 22 | 45 | 55 | 75 | 110 | 132 | |

| Overall dimensions | L | mm | 2550 | 3700 | 4700 | 5200 | 6400 | 7000 | 7500 |

| H | mm | 910 | 1280 | 1700 | 1860 | 2200 | 2600 | 2700 | |

| W | mm | 1675 | 2050 | 2350 | 2100 | 2900 | 3700 | 3830 | |

| About weight | tons | ~3.2 | ~6 | ~11.7 | ~15 | ~20 | ~38 | ~45 | |

Bearing Rolls, Harden Tooth Reducer, CE Approval

Two Roll Mill Rubber Calender

Roller type: I type

Model: XY-160X320 XY-250X620 XY-360X1120

XY-450X1400 XY-550X1700 XY-610X1730

Bearing Rolls, Harden Tooth Reducer, CE Approval

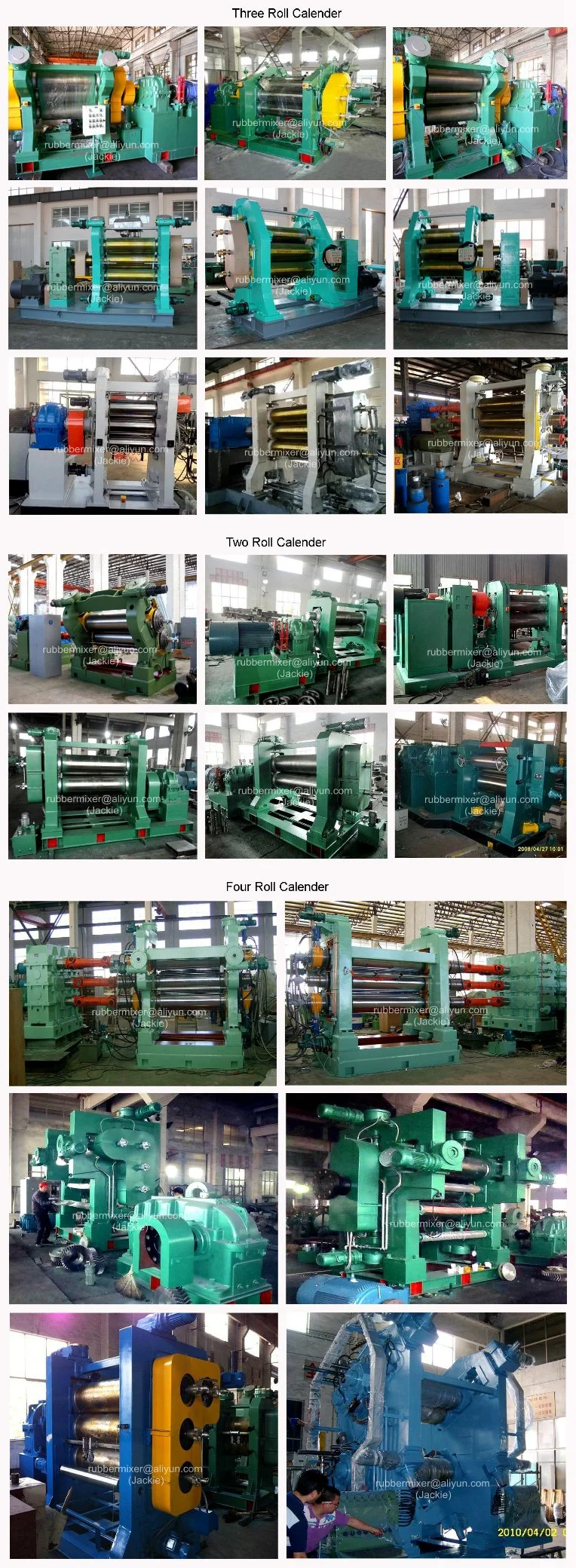

Four Roll Mill Rubber Calender

Roller type: I type, F type, S type

Model: XY-230X630 XY-360X1120 XY-400X1400

XY-450X1500 XY-610X1730 XY-710X2130

Bearing Rolls, Harden Tooth Reducer, CE Approval

What are the machine pictures?

What are the options and configurations?

1. Driving system: Bull gear drive, single shaft output for your choice.

2. Roller gap adjustment: by manual or electrical (motor drive) for your choice.

3. Roller support: by nylon bush or bearing rolls for your choice.

4. Lubrication system: by grease or oil pump for your choice.

5. Stock guider: fixed.

6. Gear reducer: ZSY harden tooth reducer.

7. Electrical components brand: CHINT, Schneider or Siemens, etc. for your choice.

What are your machine characters?

1. Roller material: chilled cast alloy iron LTG-H with hardness 68~72HSD.

2. Abrasion proof and corrosion resistant.

3. High precision gears with lower noise.

4. Speed ratio gears with necessary heating treatment.

5. High efficiency, energy saving and new design saves occupied space.

6. Interlock protection with reverse running function ensure low personal injury.

7. Our machines have CE certificate.

Company Information:

What is your company history?

Dalian Yuntai Industrial Equipments Co.,Ltd is a professional enterprise established in 1996, locates in Dalian industrial park, the most beautiful costal city in Liaoning Province. By our innovative and realistic culture, perfect internal management, good quality products service and steady market position, we have got a good reputation from our customers.

Our products involves in rubber mixing, sheeting and performing machinery, such as rubber kneader, bucket elevator, two roll mixing mill, rubber refiner, rubber cracker, batch off cooling machine, EVA foam sheet splitting machine, rubber bale cutter, rubber calender, extruder, vulcanizing press, etc.

Yuntai insists on the management strategy of "To promote the construction of modern marketing network". By our reliable quality, reasonable prices, prompt delivery and good after-sale service, we have won the trust of customers from all over the world. Our products have been distributed to Europe, South America, North America, Southeast Asia, Middle East area, Oceania, etc. We aim to create top famous brand in the world.

"Good Quality, Reasonable Price, Best Service" is our goal. We warmly and sincerely welcome custmers all over the world to visit our factory and look forward to establishing long term cooperation and solid relationship to make mutual benefit.

Pictures of workshops:

Certificates:

What certificates do you have?

Service:

What is your aftersale service?

1. Professional and quick response to your questions within 24 hours.

2. We will communicate with our production dept. and keep you updated about production progress in time.

3. Customized manufacture available for you.

4. Fast delievery to save your time.

5. Good after sale service will eliminate your worry.

6. Long guarantee period of the quality will reduce your cost and trouble.

7. Professional wooden case packing and ocean shipping control to make your order safe and sound.

8. Full sets of technical documents, instruction manual can be provided.

Payment:

What is your terms of payment?

Wire transfer: 30% advance by T/T, 70T balance by T/T before shipment.

Letter of credit: by irrevocable letter of credit at sight.

Western union: it is a fast and safe way.

Trade terms:

What is trade terms acceptable?

We can do FOB, C&F and CIF for your choice.

Contact:

How to contact you?

You can use phone to scan code to add us or leave messages (please see below):

Two Roll Mill Rubber Calender

Roller type: I type

Model: XY-160X320 XY-250X620 XY-360X1120

XY-450X1400 XY-550X1700 XY-610X1730

| Model Item | XY-2I 160x320 | XY-2I 250x620 | XY-2I 360x1120 | XY-2I 450x1400 | XY-2I 550x1700 | XY-2I 610x1730 | ||

| Roll diameter | mm | 160 | 250 | 360 | 450 | 550 | 610 | |

| Roll working length | mm | 320 | 620 | 1120 | 1400 | 1700 | 1730 | |

| Roll ratio | 1:1 | 1:1 | 1:1 | 1:1 | 1:1.08 | 1:1 | ||

| roll linear speed | m/min | 7.79 | 1.2-12 | 3-20.2 | 2.5-24.8 | 2-18.7 | 4-36 | |

| Adjusting nip range | mm | 0-4.5 | 0-6 | 0-10 | 0-10 | 0-12 | 0-15 | |

| Min.Calendering Product thickness | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| Calendering product width | mm | 250 | 580 | 920 | 1250 | 1600 | 1500 | |

| Motor power | kw | 5.5 | 15 | 37 | 45 | 75 | 90 | |

| Overall dimensions | L | mm | 2200 | 3950 | 5400 | 7113 | 7420 | 5987 |

| W | mm | 530 | 770 | 1542 | 1595 | 1760 | 1860 | |

| H | mm | 1470 | 1590 | 1681 | 2446 | 2760 | 2988 | |

| About weight | ton | ~1.2 | ~5 | ~14.5 | ~22 | ~24 | ~30 | |

Four Roll Mill Rubber Calender

Roller type: I type, F type, S type

Model: XY-230X630 XY-360X1120 XY-400X1400

XY-450X1500 XY-610X1730 XY-710X2130

| Model Item | XY-4 230x630 | XY-4 360x1120 | XY-4 400x1400 | XY -4 450x1500 | XY-4 610x1730 | XY-4 710x2130 | ||

| Roller diameter | mm | 230 | 360 | 400 | 450 | 610 | 710 | |

| Roller wording length | mm | 630 | 1120 | 1400 | 1500 | 1730 | 2130 | |

| Roller ratio | 1:1:1:1 | 0.73:1:1:0.73 | 1:1.38:1.38:1 | 1:1.5:1.5:1 | 1:1.4:1.4:1 1:1.4:1.4:1.4 | 1:1.5:1.5:1 | ||

| Middle -roll linear speed | m/min | 2.1-21 | 2-20.1 | 3-26.3 | 2.5-25 | 8-50 | 3-30 | |

| Adjusting range | mm | 0-10 | 0-10 | 0-10 | 0-6 | 20 | 0-20 | |

| Min.calendering product thickness | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.15 | 0.15 | |

| Calendering product width | mm | 500 | 920 | 1200 | 1250 | 1500 | 1900 | |

| Motor power | kW | 15 | 55 | 75 | 110 | 160 | 185 | |

| Overall dimensions | L | mm | 3800 | 3300 | 6600 | 6500 | 6580 | 7010 |

| W | mm | 930 | 940 | 1620 | 1970 | 2460 | 4150 | |

| H | mm | 1890 | 2350 | 2490 | 2740 | 2920 | 3730 | |

| About weight | tons | ~4.8 | ~14.6 | ~18.6 | ~33.5 | ~62 | ~100 | |

What are the machine pictures?

What are the options and configurations?

1. Driving system: Bull gear drive, single shaft output for your choice.

2. Roller gap adjustment: by manual or electrical (motor drive) for your choice.

3. Roller support: by nylon bush or bearing rolls for your choice.

4. Lubrication system: by grease or oil pump for your choice.

5. Stock guider: fixed.

6. Gear reducer: ZSY harden tooth reducer.

7. Electrical components brand: CHINT, Schneider or Siemens, etc. for your choice.

What are your machine characters?

1. Roller material: chilled cast alloy iron LTG-H with hardness 68~72HSD.

2. Abrasion proof and corrosion resistant.

3. High precision gears with lower noise.

4. Speed ratio gears with necessary heating treatment.

5. High efficiency, energy saving and new design saves occupied space.

6. Interlock protection with reverse running function ensure low personal injury.

7. Our machines have CE certificate.

Company Information:

What is your company history?

Dalian Yuntai Industrial Equipments Co.,Ltd is a professional enterprise established in 1996, locates in Dalian industrial park, the most beautiful costal city in Liaoning Province. By our innovative and realistic culture, perfect internal management, good quality products service and steady market position, we have got a good reputation from our customers.

Our products involves in rubber mixing, sheeting and performing machinery, such as rubber kneader, bucket elevator, two roll mixing mill, rubber refiner, rubber cracker, batch off cooling machine, EVA foam sheet splitting machine, rubber bale cutter, rubber calender, extruder, vulcanizing press, etc.

Yuntai insists on the management strategy of "To promote the construction of modern marketing network". By our reliable quality, reasonable prices, prompt delivery and good after-sale service, we have won the trust of customers from all over the world. Our products have been distributed to Europe, South America, North America, Southeast Asia, Middle East area, Oceania, etc. We aim to create top famous brand in the world.

"Good Quality, Reasonable Price, Best Service" is our goal. We warmly and sincerely welcome custmers all over the world to visit our factory and look forward to establishing long term cooperation and solid relationship to make mutual benefit.

Pictures of workshops:

Certificates:

What certificates do you have?

Service:

What is your aftersale service?

1. Professional and quick response to your questions within 24 hours.

2. We will communicate with our production dept. and keep you updated about production progress in time.

3. Customized manufacture available for you.

4. Fast delievery to save your time.

5. Good after sale service will eliminate your worry.

6. Long guarantee period of the quality will reduce your cost and trouble.

7. Professional wooden case packing and ocean shipping control to make your order safe and sound.

8. Full sets of technical documents, instruction manual can be provided.

Payment:

What is your terms of payment?

Wire transfer: 30% advance by T/T, 70T balance by T/T before shipment.

Letter of credit: by irrevocable letter of credit at sight.

Western union: it is a fast and safe way.

Trade terms:

What is trade terms acceptable?

We can do FOB, C&F and CIF for your choice.

Contact:

How to contact you?

You can use phone to scan code to add us or leave messages (please see below):