This machine features small and portable appearance, big force, low noise and easy to operate. The buckling amount can be precise adjusted through a scale. It makes the mould base division to be more even through the double inclined plane eight-flap mould seat equipped with a high accuracy guiding device.

1) Using forge steel machine head, more durabler than general steel.

2) CNC operation panel, simple controls and operation.

3) CNC system, high crimp accuracy which is within 0.01mm.

4) Equipped with a foot pedal, very convenient for free hand operate.

5) Magnetic dies (Patented), very convenient to remove and install dies.

How can I know the machine detail parts?

| Hose Crimping Machine | |

| Model | HHP52-F |

| Crimping Range | 1/4" TO 2" |

| Max Crimping Range | 500T |

| Scale accuracy | 0.02mm |

| Rated Pressure | 31.5Mpa |

| Oil pump Displacement | 5ml/rad(380V 50HZ);2.5ml/rad(220V 50HZ) |

| Die Quantity | 10 sets |

| Warranty | 3 years |

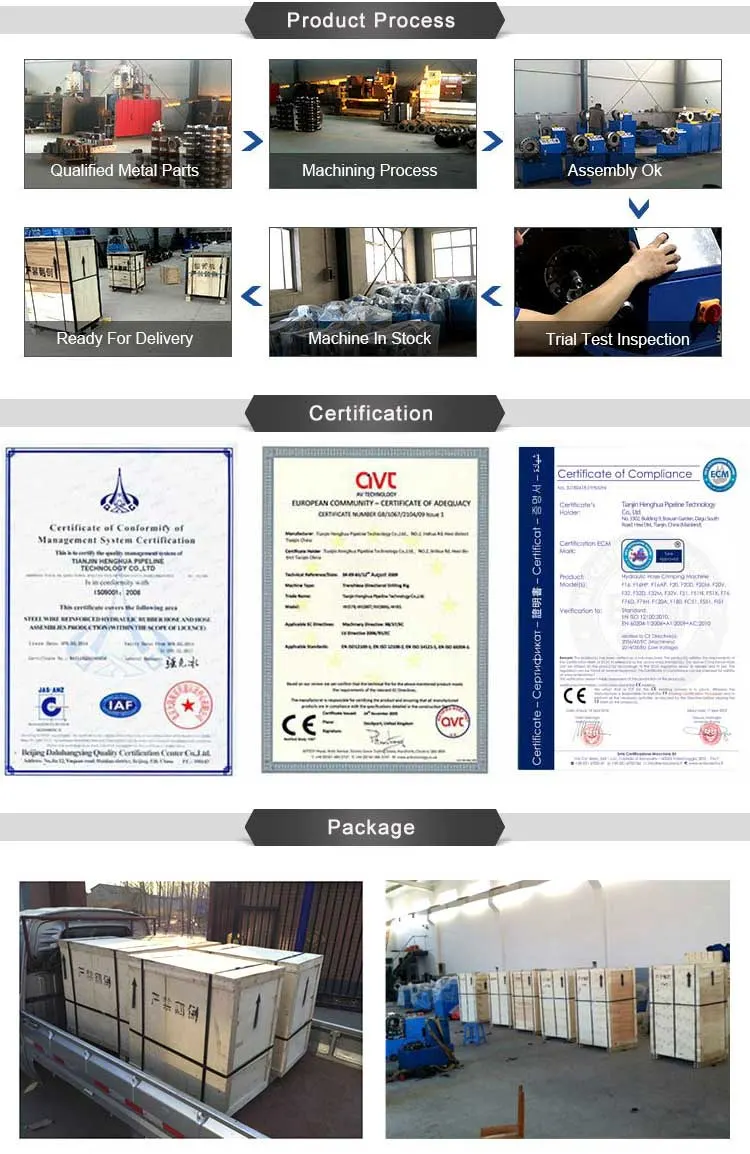

| Package | Wooden Case |

| Dimensions(L×W×H) | 700*900*1400mm |

| Weight | 350KG |

1.When buckling, make the joint to locate the mould center as much as possible, the joint is not buckled on the hex nut.

2.Prevent tool and other foreign matter from entering the locking head.

3.After the work is finished for each time, the eight-block mould base must be made to extend to the greatest extent, this can make the spring to be at extension status. If not, the spring will be damage.

4.When working, the hand should not stretch into the locking head.

5.The power supply must be switched off when maintenance is done.

Maintenance and Care

Maintenance

The hydraulic oil in the oil tank should be frequently checked, if oil amount is found to be insuf- ficient, the oil shall be timely supplemented. If the oil liquid is polluted, it shall be filtered or replaced.

The locking head shall keep internal cleanliness. Avoid the foreign matters during processing to enter into the locking head oil cylinder via the mould to affect the normal use. Wipe out the foreign matters, which are brought by the mould body in time when buckling the joint.

Frequently fill suitable grease into the mould body for lubrication.

Promise

We will provide a guarantee to keep the machine in good repair within 12 months from the day when the machine is purchased. All fitting troubles will be free of charge repaired (or replaced if necessary) during the guarantee period. The damage resulted from improper use o accident damage does not belong to free of charge repair range.

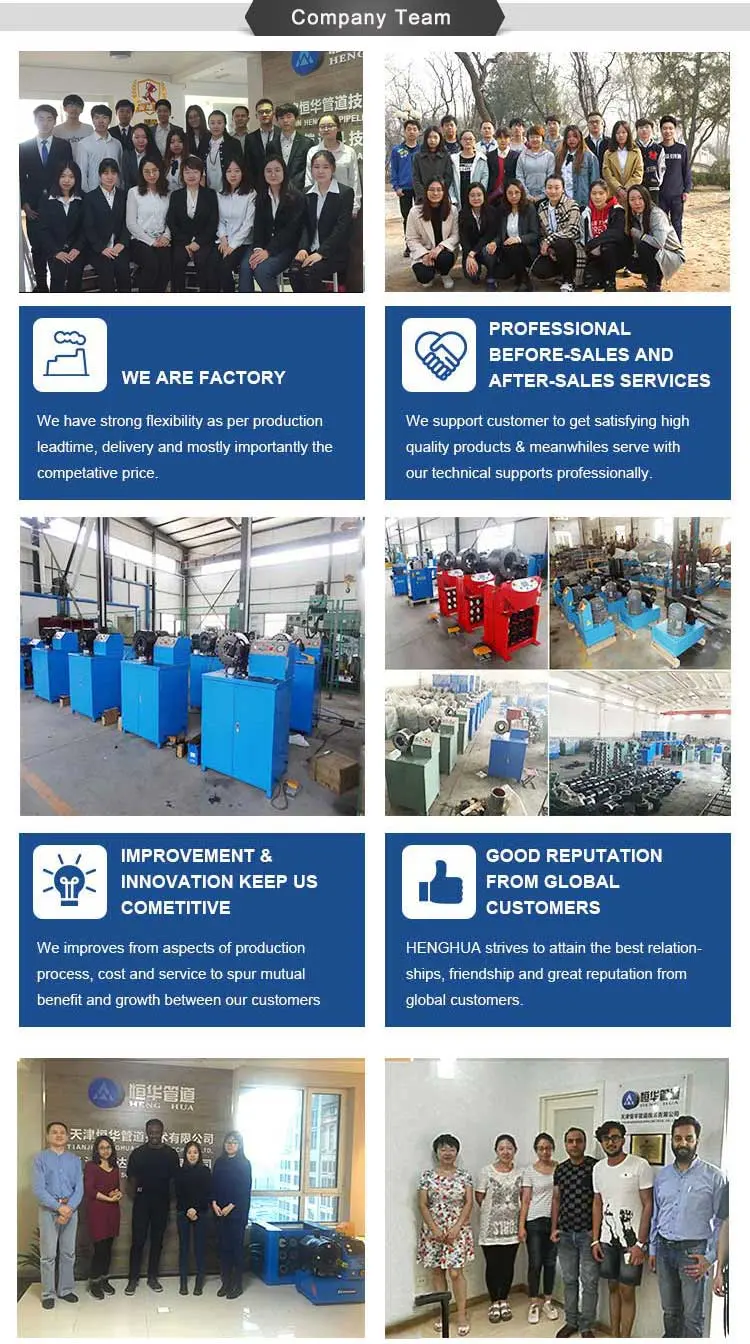

1. What level of service do you provide ?

*Your inquiry will be replied in 24 hours.

*Eight continuous years as an Alibaba Gold supplier and more than 25 years industrial technology and manufacturing experience .

* We offer free spare parts and service within 14 month warranty period.

* Technology Support by providing operation training videos .

* Professional after-sales service team.

* Give reasonable offers with the best quality.

2. What is our advantages?

* Competitive price: We can meet your budget and best-selling business very well.

* OEM Accepted: We can produce customized design.

* Good Service: We treat clients as friends and provide problem solving anytime you need.

* Good Quality: We have strict quality control system. Good reputation in the market.

* Fast & Delivery: We have big discount from forwarder (Long-term Contract).

* Door To Door Service.

3. Can you customize the machine for the customer?

Yes. We can, we also provide OEM for customers; If you need customized services, please contact us

4. What is the MOQ?

We usually provide 1 set for customers to test.

Troubleshooting

| Trouble phenomena | Trouble reason | Eliminating method |

| Machine has not action | Oil tank has not been filled with oil | Fill oil as per requirement |

| Motor rotation direction is not correct | Regulate two phase lines | |

| Electric trouble | Overhaul electric circuits | |

| Scale is damaged | The scale is fastened on the oil cylinder end face by the screw | Regulate the scale as per the instruction to make scale to telescope freely |

| Conductor at scale location is connected with scale | Anew connect the scale conductor to make it to be insulated from scale base | |

| Electric trouble | Overhaul electric circuits and electric elements | |

| Scale conductor cutting | Anew connect scale | |

| System pressure is excessively low | Adjust buckling pressure-regulating valve | |

| No buckling | The valve core of solenoid reversal valve is seizured by foreign matters | Dismount solenoid reversal valve, use gasoline to clean the valve core. |

| Electric trouble | Overhaul electric circuits | |

| Mould is not opened | Opening mould pressure is excessively low | Adjust opening mould pressure regulating valve |

| Electric trouble | Overhaul electric circuits | |

| Big noise | Installation is not stable | Conduct horizontal stable installation |

| Hydraulic oil is excessively dirty | Filter or change it | |

| Filter is blocked | Use gasoline to clean the filter | |

| Mould base crawls | Gas in the hydraulic oil has not bee exhausted completely | Suitable unscrew the bleed screw, make the piston in the oil cylinder to move back to last position to exhaust gas, then screw down bleed screw. |

| Lubrication is poor | Smear grease on the working inclined face of mould base | |

| Oil leakage | Joint is not tightened closely | Tighten the oil pipe joint |

| Sealing washer is damaged. |

A parameter list of the tooting and the press force for every type of rubble tube(for reference)

order | Inner diameter of the rubble tube | Outer diameter of the rubble tube | Used tooting | Half locking & pressing meter pressure MPa | Whole locking & pressing meter pressure MPa | |

1 | Φ6 | Φ15 Φ17 | Φ15 | 5.5 6 | 6~8 9~11 | |

2 | Φ10 | Φ19 Φ21 | Φ21 | 6.5~7 7.5~8 | 10~11 13~16 | |

3 | Φ13 | Φ23 Φ25 Φ27 | Φ25 | 8.5~9 10~11 | 14~17 15~18 | |

4 | Φ16 | Φ26 Φ28 | Φ28 | 9~10 10~11 | 15~18 18~22 | |

5 | Φ19 | Φ29 Φ31 Φ35 | Φ30 | 9 11~12 22~24 | 15~17 20~22 29~31 | |

6 | Φ22 | Φ32 Φ34 Φ38 | Φ34 | 12~13 14~16 20~25 | 17~19 19~21 25~30 | |

7 | Φ25 | Φ36 Φ38 Φ42 | Φ38 | 10~11 15~16 26~28 | 16~18 20~24 28~32 | |

8 | Φ32 | Φ44 Φ46 Φ50 | Φ42 Φ45 | 12~13 16~18 32 | 18~22 30~34 32~38 | |

9 | Φ38 | Φ50 Φ52 Φ60 | Φ50 Φ55 | 14 20 26~30 | 22~26 28~32 44~48 | |

10 | Φ51 | Φ63 Φ65 Φ69 | Φ60 Φ65 | 25 30 35 | 26~28 40 48 | |

Is there any other type machine I can choose?

We offer various types of hose crimping machine. If you are interested in any one, Any questions are welcome.