Rubber mixing mill,two-roll open mixing mill rubber machine

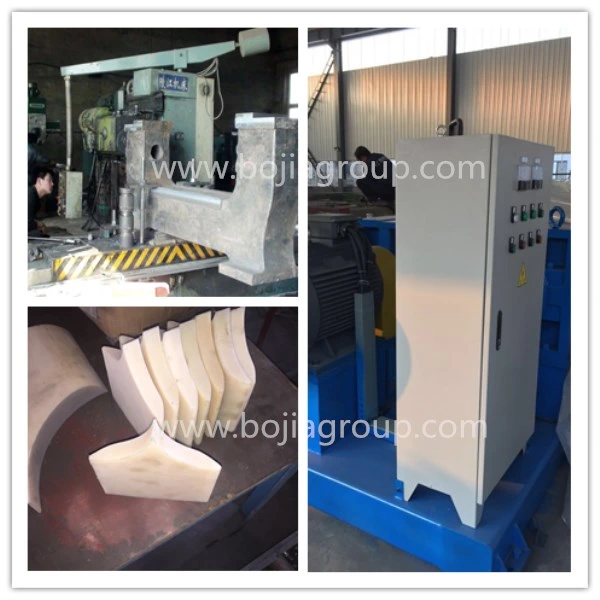

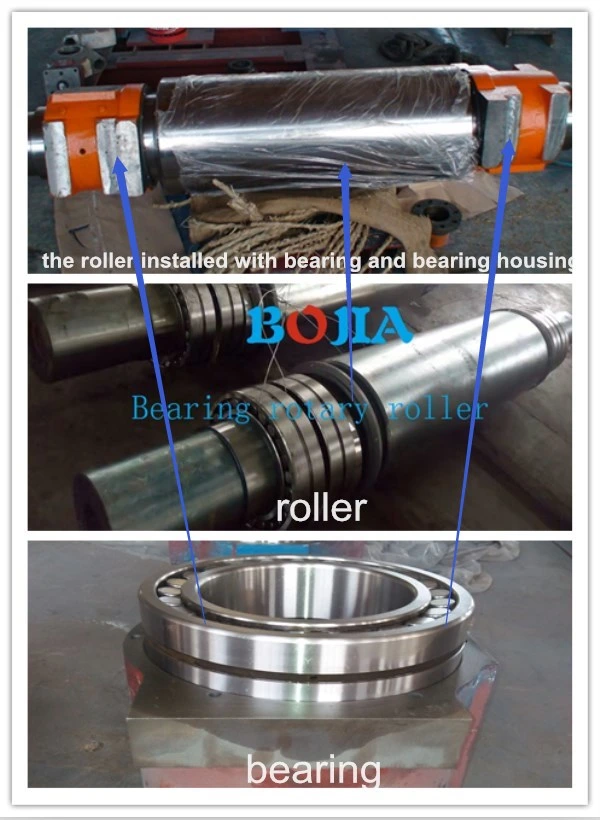

Production

Hard and wearable surface

Having overload protection devices

Perfect emergency stop device

Stock pan is easy to clean up with dislodging device.

The transmission system has compact structure,low noise and high efficiency.

Product Uses

Hydraulic Press Machine Application

Vulcanizing machine is suitable for a variety of vulcanized rubber products, a variety of advanced thermoset compression

molding pressing equipment.

1. Rubber products processing line(tyres,shoes,handbags,latex gloves,sport balls,mousepad,conveyors,rubber

sheets&tiles,

rubber band,seals,insulation boards,etc.,)

2. Plastic runway and artificial grass production line

This machine is mainly used for vulcanizing flat type tape and plastic sheet,just as conveyor belts and rubbertiles.

This machine is mainly used for the production of various kinds of EVA foam slippers, foam board, rubber, bags lining,

insulating material, sports protective material, diving suits, jackets sponges thermoset foam rubber and plastic products

of special equipment.

Flow chart of rubber vulcanizing machine

Mixing: Pour the rubber granules and coloring pigment into the rubber mixing machine, with some adhesive, then begin

stiring. It will take 4-6 mins to be done.

Weighing: weigh the stirred rubber powder according to the floor tiles thickness you want to make.

Paving and Pressing: pour the needed quantity rubber powder into the mould, and float it by trowel. On the bottom ,can

be with some

coarse and black rubber powder, but on the surface should be with fine and colored powder, it can ensure your tiles quality.

Vulcanization Moulding: Put the mould on the vulcanizer layer, generally , it take 3/8 mins to make the tiles,time difference

based

on the thickness of the tiles you ready to make. After finished, it will automaticlly separated, then put it somewhere to dry.

Inspecting: Inspect the tiles' surface . If no aberration, no flaw, then it is of high quality products.

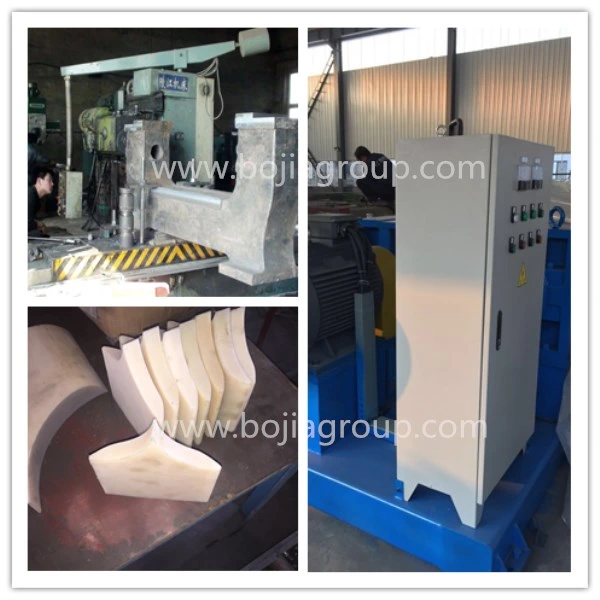

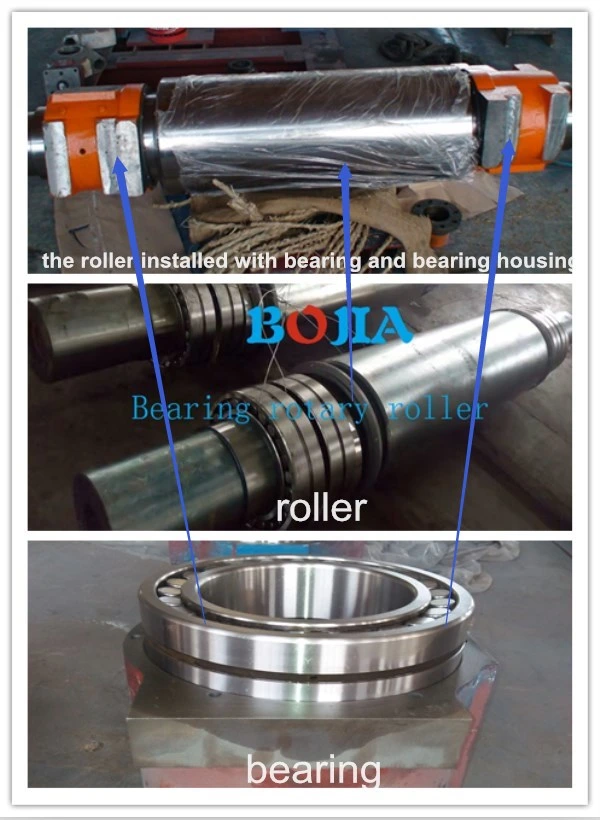

Production

Hard and wearable surface

Having overload protection devices

Perfect emergency stop device

Stock pan is easy to clean up with dislodging device.

The transmission system has compact structure,low noise and high efficiency.

| Item | XK-160 | XK-250 | XK-360 | XK-400 | XK-450 | XK-550 | XK-560 | XK-660 | XK-710 | |

| Roll diameter | mm | 160 | 250 | 360 | 400 | 450 | 550 | 560-510 | 660 | 710 |

| Roll working length | 320 | 620 | 900 | 1000 | 1200 | 1500 | 1530 | 2130 | 2200 | |

| Front roll linear speed | r/min | 9 | 16.3 | 16.7 | 19.3 | 21.8 | 22.5 | 27.2 | 28 | 31.9 |

| Speed ratio of rolls | 01: 01.4 | 01: 01.1 | 01: 01.3 | 01: 01.3 | 01: 01.3 | 01: 01.2 | 01: 01.2 | 01: 01.2 | 01: 01.5 | |

| Max roll space | mm | 4.5 | 8 | 10 | 10 | 12 | 16 | 15 | 0.5-15 | 0.5-15 |

| Compound feeding capacity | kg | 1-2 | 10-15 | 20-25 | 18-35 | 50 | 50-65 | 50-65 | 165 | 190 |

| Motor power | kW | 5.5 | 18.5 | 30 | 45 | 55 | 110 | 90 | 240 | 280 |

| Dimensions(L× W× H) | ||||||||||

| L | mm | 1133 | 2722 | 4200 | 4920 | 5405 | 6646 | 6270 | 7280 | 8185 |

| W | mm | 920 | 1115 | 1780 | 1780 | 1740 | 2736 | 2282 | 3400 | 3910 |

| H | mm | 1394 | 1345 | 1760 | 1800 | 1790 | 2105 | 2000 | 2530 | 2270 |

| Gross weight | T | ~2 | ~3.2 | ~6.5 | ~8 | ~11.4 | ~22 | ~22.5 | ~49 | ~51 |

Hydraulic Press Machine Application

Vulcanizing machine is suitable for a variety of vulcanized rubber products, a variety of advanced thermoset compression

molding pressing equipment.

1. Rubber products processing line(tyres,shoes,handbags,latex gloves,sport balls,mousepad,conveyors,rubber

sheets&tiles,

rubber band,seals,insulation boards,etc.,)

2. Plastic runway and artificial grass production line

This machine is mainly used for vulcanizing flat type tape and plastic sheet,just as conveyor belts and rubbertiles.

This machine is mainly used for the production of various kinds of EVA foam slippers, foam board, rubber, bags lining,

insulating material, sports protective material, diving suits, jackets sponges thermoset foam rubber and plastic products

of special equipment.

Flow chart of rubber vulcanizing machine

Mixing: Pour the rubber granules and coloring pigment into the rubber mixing machine, with some adhesive, then begin

stiring. It will take 4-6 mins to be done.

Weighing: weigh the stirred rubber powder according to the floor tiles thickness you want to make.

Paving and Pressing: pour the needed quantity rubber powder into the mould, and float it by trowel. On the bottom ,can

be with some

coarse and black rubber powder, but on the surface should be with fine and colored powder, it can ensure your tiles quality.

Vulcanization Moulding: Put the mould on the vulcanizer layer, generally , it take 3/8 mins to make the tiles,time difference

based

on the thickness of the tiles you ready to make. After finished, it will automaticlly separated, then put it somewhere to dry.

Inspecting: Inspect the tiles' surface . If no aberration, no flaw, then it is of high quality products.