Why choose our company?

1. AAA grade credit enterprise.

2. With 14 years experience in manufacturing rubber machines has become one of the biggest company in China.

3. Exported to more than 20 contries with good quality. Example: The good year company in Chile...

Management Concept: Survive by Quality, Develop by Credit, Innovate by Technology, Improve by precision.

Times Concept: People Oriented, Scientific Development, Advance with Times, Innovative creation.

Work Concept: Hardworking Practical, Conscientious and Meticulous.

Why choose our this machine?

1. With completely sealed condition, materials are mixed or plasticized under certain pressure, controllable temperature, which makes high production efficiency and obtains excellent stable quality.

2. Spiral angle and over lapping length of the blades of the rotors are of reasonable design and make the materials to be dispersed uniformly.

3. Surface where is contracted with the machine are all plated with hard chromium and polished, which is corrosion-resistant and wear-resistant.

4. Jacket construction is adopted in parts that surfaces contact with materials to achieve excellent water-cooling or steam-heating effect and fit in with the needs of plastics and rubber processing technology.

5. Feeding from back door on the frame(or separate top door) is convenient ofr continuous process operation in production line. The mixing chamber is able to turn forward by 140 around th front rotors to discharge and is easy for changing pigments and cleaning the chamber.

6. Programmable logic controller (PLC) is adopted in the electric-control system, which has reliable control function and alarm function, and interlock safety-protection function and it is provided with serial interface of net.

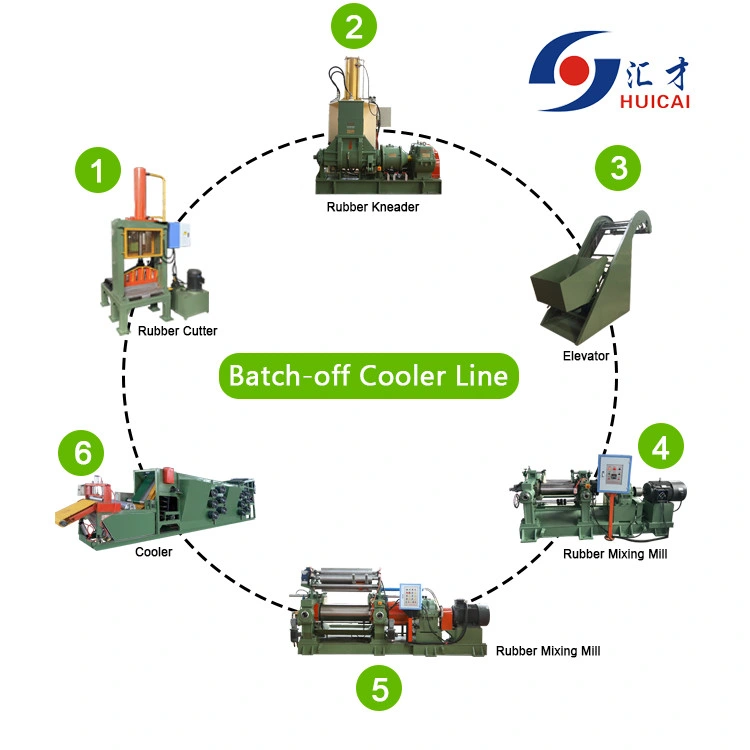

RUBBER MIXING PRODUCTION LINE

Type | X(S)N- 3×32 | X(S)N-10×32 | X(S)N-20×32 | X(S)N- 35×30 | X(S)N-55×30 | X(S)N-75×30 | X(S)N-110×30 | X(S)N-150×30 | |

Total Volume of kneading chamer | L | 8 | 25 | 45 | 75 | 125 | 180 | 250 | 325 |

Total volume of mixing chamber | L | 3 | 10 | 20 | 35 | 55 | 75 | 110 | 150 |

Driving motoal power | KW | 5.5 | 15 | 30 | 55 | 75 | 110 | 185 | 220 |

Tipping motor power | KW | 0.55 | 1.1 | 1.5 | 2.2 | 3.0 | 4.0 | 5.5 | 5.5 |

Tipping angle | 135° | 140° | 140° | 140° | 140° | 140° | 140° | 140° | |

Rotational speed of the rotor(front\back) | r/min | 0~60, 32/24.5 | 30/23.5 | 30/25 | 30/24.5/ 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 |

Flow rate of compressed air | Mpa | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

Flow rate of compressed air | M3/min | ≥ 0.3 | ≥0.5 | ≥0.7 | ≥0.9 | ≥1.0 | ≥1.0 | ≥1.5 | ≥1.5 |

Pressure of cooling water (rubber mixing) | Mpa | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

Pressure of heated steam(Plastication) | Mpa | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 | 0.5-0.8 |

Overall dimensions (LXWXH) | MM | 1660×960 ×1750 | 2580×1300 ×2280 | 2630×1520 ×2550 | 3200×1900 ×2945 | 3360×1950 ×3050 | 3760×2143 ×31350 | 4075×2712 ×3580 | 4200×3200 ×4000 |

Weight | Kg | 2000 | 3300 | 4500 | 6500 | 7200 | 10000 | 14500 | |

CONTACT: