Application:

Rubber kneader is mainly used for rubber and other assistant mixing and plasticizing under the condition of enclosed, pressured space inside the kneader.

Model number : X(S)N-3L,5L,10L,20L,25L,35L/55L/75L/110L/150L/200L Rubber Dispersion Kneader Machine.

Main features:

5. High efficiency, energy saving and saving occupied space.

6. Interlock protection ensure low personal injury.

7. With CE certificate

Main technical specifications:

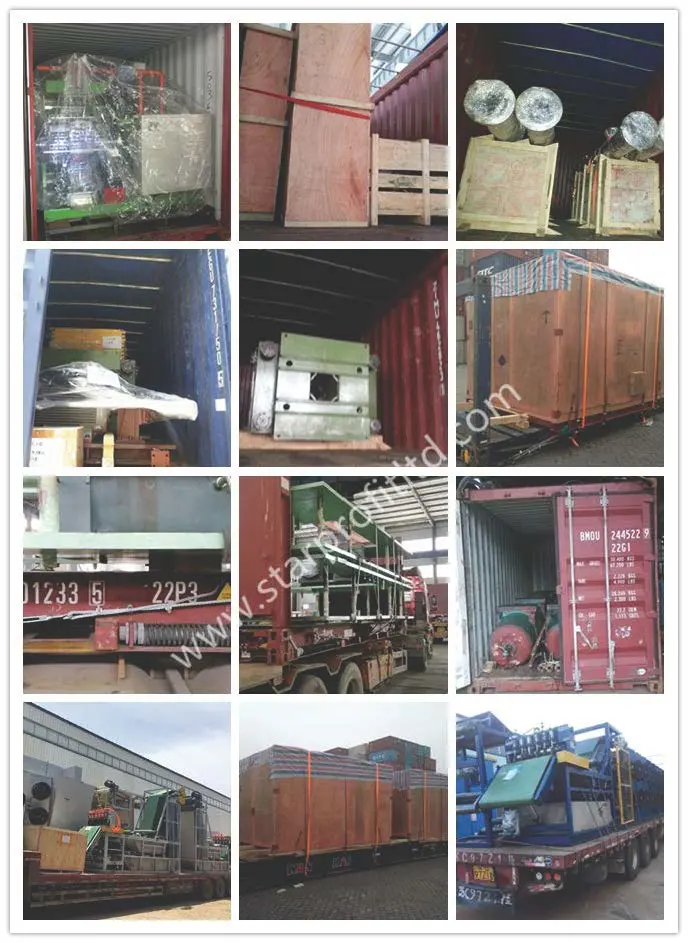

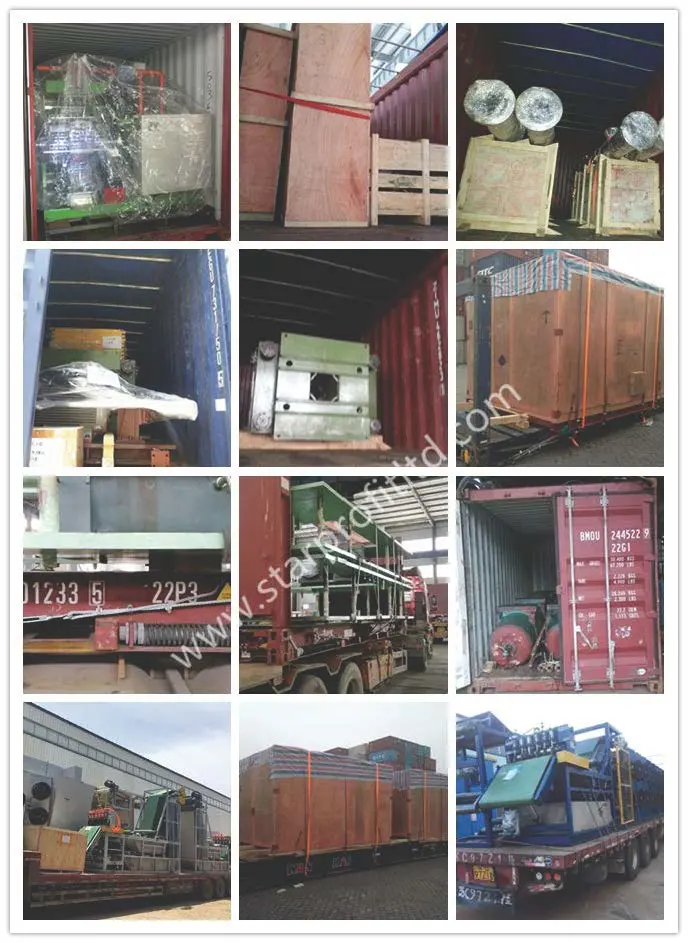

Machine packing and shipping:

Certificates:

Customer visits:

Participate in the exhibition:

After-sale services:

1. Professional and quick response to your questions within 24 hours.

2. We will communicate with our production dept. and keep you updated about production progress in time.

3. Customized manufacture available for you.

4. Fast delivery to save your time.

5. Good after sale service will eliminate your worry.

6. Long guarantee period of the quality will reduce your cost and trouble.

7. Professional wooden case packing and ocean shipping control to make your order safe and sound.

8. Full sets of technical documents, instruction manual can be provided.

Trade terms:

We can do FOB, C&F and CIF for your choice

FAQ:

1. How to install the new machine?

Firstly, our machines are designed easy for installation; and we also supply a very detailed operation manual and installation videos to you. If needed, we'll arrange the technical engineer to service overseas.

2. How to solve the problems during using the machines?

We have special after-sale team ready to solve the problems for our customers at the first time. Firstly, customers can describe the problems to us by email or telephone; sometimes we need you to supply the problem pictures and videos for our technical engineers for reference. After finding the problem, we'll discuss and give you the most effective solution in a short time. If needed, we'll arrange the most experienced engineer to go to your factory for solving your problems as soon as possible.

3. Warranty period and spare parts supply?

We have one year warranty and life-long maintenance. During the first year, if any parts broken not occurred by human, we will supply the new replacement parts freely.

4. Do you supply OEM service?

Yes. OEM service is available. Our professional designer would make your private idea into being. We will protect your sales area, ideas of design and all your private information.

And we are negotiating with agents and distributors in many countries.

5. Do your machines have Invention Patent?

Yes. We achieved core software copyright and patents technology authorizing.

Thanks a lot for your attention on our Machines. Please feel free to leave the message of your specific requirements, we will customize the solution for you.

Rubber kneader is mainly used for rubber and other assistant mixing and plasticizing under the condition of enclosed, pressured space inside the kneader.

Model number : X(S)N-3L,5L,10L,20L,25L,35L/55L/75L/110L/150L/200L Rubber Dispersion Kneader Machine.

Main features:

1. Kneader machine consists of body welded with high quality steel plates and two pieces of side plates. The chamber, rotors and piston ram are all jacketed structure for the ingoing of steam, oil and water for heating and cooling to suit the various requirement for the process of mixing and plastication.

2. Dispersion Kneader Machine Motor, reducer adopts hardened tooth surface gear, that has low noise and can save 20% electricity or power and has a long service life.

3. The machine PLC control system adopts Mitsubishi/Omron. Electric parts adopt ABB or US Brand, that will ensure good performance.

4.Hydraulic pressure tilting mechanism with the advantage of fast discharging materials and 140 tilt angle.3. The machine PLC control system adopts Mitsubishi/Omron. Electric parts adopt ABB or US Brand, that will ensure good performance.

5. High efficiency, energy saving and saving occupied space.

6. Interlock protection ensure low personal injury.

7. With CE certificate

Main technical specifications:

| Model | X(S)N -3x32 | X(S)N -10x32 | X(S)N -20x32 | X(S)N -35x30 | X(S)N -55x30 | X(S)N -75x30 | X(S)N -110x30 | X(S)N -150x30 | X(S)N -200x30 |

| Total volume of mixing chamber L | 8 | 25 | 45 | 75 | 125 | 180 | 250 | 325 | 440 |

| Working volume of mixing chamber L | 3 | 10 | 20 | 35 | 55 | 75 | 110 | 150 | 200 |

| Main motor power kw | 5.5 | 15 | 30 | 55 | 75 | 110 | 185 | 220 | 280 |

| Rotational speed of rotor (front/rear) r/ min | 32/25.8 | 32/25 | 32/27 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 |

| Tilting angle degree ° | 135 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 |

| Tilting motor power kw | 0.55 | 1.1 | 1.5 | 2.2 | 2.2 | 4 | 4 | 5.5 | 7.5 |

| Pressure of compressed air Mpa | 0.5-0.8 | 0.5-0.8 | 0.5- 0.8 | 0.5-0.8 | 0.6- 0.8 | 0.6- 0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Pressure of cooling water Mpa | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3- 0.4 | 0.3- 0.4 | 0.3-0.4 | 0.3-0.4 |

| Heating steam pressure (plastics mixing) Mpa | 0.5-0.8 | 0.5- 0.8 | 0.5- 0.8 | 0.5-0.8 | 0.5- 0.8 | 0.5- 0.8 | 0.5- 0.8 | 0.5-0.8 | 0.5-0.8 |

| Overall dimensions mm | 1660x 960 ×1750 | 2580 x 1300 ×2280 | 2630 x 1520 ×2550 | 3200 x 1900 ×2950 | 3280x 1930 ×3070 | 3330x2620 ×3340 | 3930x3000 ×3660 | 4200x3300 ×3900 | 4520x3400 X4215 |

| Approx. Weight t | ~2 | ~3.3 | ~4 | ~6.3 | ~7.5 | ~10.3 | ~14.2 | ~19.5 | ~22.5 |

Machine packing and shipping:

Certificates:

Customer visits:

Participate in the exhibition:

After-sale services:

1. Professional and quick response to your questions within 24 hours.

2. We will communicate with our production dept. and keep you updated about production progress in time.

3. Customized manufacture available for you.

4. Fast delivery to save your time.

5. Good after sale service will eliminate your worry.

6. Long guarantee period of the quality will reduce your cost and trouble.

7. Professional wooden case packing and ocean shipping control to make your order safe and sound.

8. Full sets of technical documents, instruction manual can be provided.

Trade terms:

We can do FOB, C&F and CIF for your choice

FAQ:

1. How to install the new machine?

Firstly, our machines are designed easy for installation; and we also supply a very detailed operation manual and installation videos to you. If needed, we'll arrange the technical engineer to service overseas.

2. How to solve the problems during using the machines?

We have special after-sale team ready to solve the problems for our customers at the first time. Firstly, customers can describe the problems to us by email or telephone; sometimes we need you to supply the problem pictures and videos for our technical engineers for reference. After finding the problem, we'll discuss and give you the most effective solution in a short time. If needed, we'll arrange the most experienced engineer to go to your factory for solving your problems as soon as possible.

3. Warranty period and spare parts supply?

We have one year warranty and life-long maintenance. During the first year, if any parts broken not occurred by human, we will supply the new replacement parts freely.

4. Do you supply OEM service?

Yes. OEM service is available. Our professional designer would make your private idea into being. We will protect your sales area, ideas of design and all your private information.

And we are negotiating with agents and distributors in many countries.

5. Do your machines have Invention Patent?

Yes. We achieved core software copyright and patents technology authorizing.

Thanks a lot for your attention on our Machines. Please feel free to leave the message of your specific requirements, we will customize the solution for you.